Cavity Wall Insulation Removal – The Ultimate Guide

Cavity wall insulation can be problematic when it gets wet, which is why in recent years there has been a big shift towards removing failing or poorly performing cavity wall insulation in order to prevent the long list of problems it causes.

Before you decide if removal is the right choice, it helps to understand the common causes of failure and how to confirm whether the insulation is the root of the problem.

In this guide we cover:

- What causes cavity wall insulation to fail

- How to confirm the cause

- When removal is the best option

- What alternative options you have

What Is Cavity Wall Insulation?

Prior to the 1920’s, most homes was built in the same way, with what is known as a solid wall construction.

After the 1920’s however, properties were generally built to have a cavity wall, which is two layers of single skin brickwork with a gap in the middle. This cavity was designed to prevent rainwater from seeping through the walls and into the internal wall, helping reduce the risk of damp.

In attempts to make properties more energy efficient, new ways of insulation were also developed, including cavity wall insulation, which is the process of adding insulating materials to the cavity wall of a property in order to retain heat within the property.

A large proportion of homes built after the 1990’s were built with cavity wall insulation, however other properties that were not installed with cavity wall insulation at the time of construction often had this installed retrospectively.

Cavity wall insulation is generally made of insulating wool or polystyrene beads and can be installed within the cavity when the building is constructed by applying insulating boards or it can be injected into the cavity through drill holes in the outside walls, that are then sealed with cement.

- By December 2020, there were 14.3 million properties with cavity wall insulation, which is 70% of all properties with a cavity wall

- In the ECO scheme, 32% of measures have been adding cavity wall insulation

- A survey of 250,000 properties across the UK found that one-third of homes are well insulated, one-third have no insulation and one-third have damp or poorly performing insulation

How To Identify Cavity Wall Insulation

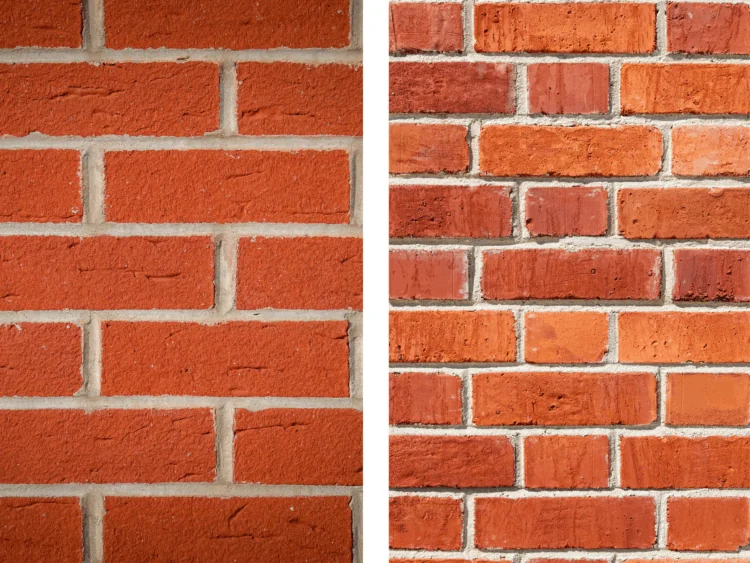

There are a few ways you can check at home whether you have cavity wall insulation. The first step is to establish if you have a solid wall or a cavity wall, which can be done by looking at the alignment of bricks.

If the bricks are laid uniformly across the wall, this is a sign that it is a cavity wall. If there are bricks placed horizontally, creating an uneven pattern, this is a sign that it is a solid wall.

The age of the property will also give you an indication of the type of construction.

- Homes built before the 1920’s are often solid wall

- Homes after 1920’s are more than likely cavity wall

Once you have identified whether there is a solid wall or a cavity wall, the next step is to establish whether there is cavity wall insulation.

If there are any small drill holes across the lower part of a property, this is an indication that there has been cavity wall insulation injected into the property. Furthermore, if the property was built in the last 20 years, cavity wall insulation was likely to be added when it was constructed.

If there are no signs of cavity wall insulation being added and there are no records of what insulation is present, it’s recommended you ask a professional to inspect the property to be sure.

Problems Caused By Cavity Wall Insulation

Research suggests that there is a direct link between cavity wall insulation (CWI) and damp problems, which is caused by a number of factors.

In most cases, the cavity wall insulation in the form of rigid foam boards is fixed to the inner wall leaving a small gap in the cavity to allow any rainwater to run down.

This small gap ensures that there is no bridge for moisture to absorb from the external wall into the insulation and then into the internal wall.

When insulation is installed properly during the construction phase, it should not suffer from problems like penetrating damp.

Issues arise when insulation is either installed poorly or retrofitted after construction.

When the cavity wall is injected with an insulating material, the risk of cavity wall insulation causing damp problems can be high. According to the Building Research Establishment (BRE):

“There can be an increased risk of rain penetration if a cavity is fully filled with insulation, i.e. moisture is able to transfer from the outer to the inner leaves resulting in areas of dampness on internal finishes. Rainwater, under certain driving rain conditions, can penetrate the outer leaf of masonry leading to wetting of the cavity insulation, a reduced thermal performance and damage to internal finishes.”

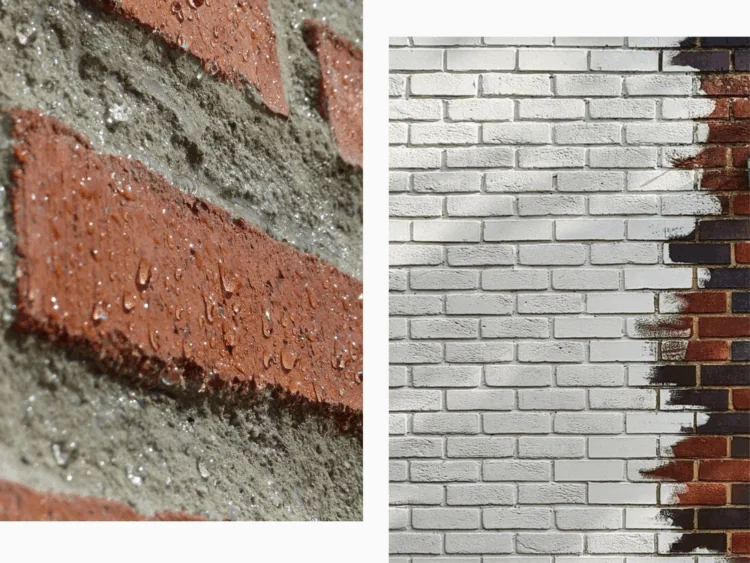

When any external wall is exposed to wind-driven rain, the substrate becomes saturated with water as brick, stone, concrete and render are all porous. Cavity walls were originally designed to stop this water from soaking through into the internal wall of a property, which causing significant problems such as black mould.

Poorly fitted insulation acts as a bridge for this water to soak into the inner wall and cause damp, creating the same problem that cavity walls were designed to solve.

Other moisture-related issues include:

- Gaps in the insulation can create cold spots

- Insulation sinking with the cavity over time

- Blocked air vents that reduce breathability

- Water vapour building up inside the property

These problems are what lead to many homeowners taking the decision to have cavity wall insulation removed or extracted, to prevent cavity wall insulation being saturated with moisture and ultimately having a negative impact on the energy efficiency of a property.

Cavity Wall Insulation Removal

If you have identified that cavity wall insulation is leading to problems you may decide that cavity wall insulation removal is the best option.

This is done by blowing compressed air into the cavity while a vacuum collects the insulation, rubble and debris from the cavity wall.

It’s a specialist process that must be undertaken by professionals, so we recommend that you seek a reputable insulation specialist regarding removing cavity wall insulation.

Checkatrade estimate that on average, the cost of cavity wall insulation removal starts from around £1,680 and can rise to £2,520 for a typical detached property.

An Alternative To Cavity Wall Insulation Removal

If your cavity walls are experiencing problems with moisture, there are a number of things you can do before you decide to remove the insulation.

Check your guarantee

Many cavity wall insulation installers will often offer a guarantee of quality covered by the Cavity Insulation Guarantee Agency (CIGA), which means if you have any documentation from when cavity wall insulation was installed, this can help you get assistance with poorly fitted insulation.

Manage moisture

Due to the nature of cavity wall insulation getting saturated with moisture, by preventing this moisture entering the wall, you help manage the problems caused by it.

Applying a treatment to the external wall to prevent the moisture absorbing into the wall is a process that can be done by yourself at home and can cost less than the price of extracting cavity wall insulation.

When it comes to applying anything to exterior walls, the most important thing is to ensure that the breathability of the property is not compromised.

Products like brick sealers repel rain, but also trap water vapour, which prevents the wall from breathing and leads to more problems than they solve.

Breathability can be measured using an SD value. The lower the number, the higher the breathability. Always check the SD value of a product to ensure it won’t damage your walls.

Learn more: How breathability works

The ability to keep rain out but not block breathability sounds impossible, but the answer lies in cutting-edge nano-technology.

The idea is simple – rain as a liquid cannot pass through and is repelled, while water vapour as a gas remains small enough to move out of the wall as normal, letting the masonry breathe and stay dry.

This comes in two forms:

- Emperor Masonry Paint – a coloured paint for bare or previously painted exterior walls.

- Emperor Masonry Creme – an invisible treatment for bare masonry that keeps the natural look of the wall.

By keeping the external wall dry and breathable, you reduce the amount of moisture that reaches the cavity, helping the insulation perform as it’s designed to.

If the insulation is already wet, this gives the cavity time to dry out by preventing further saturation, while allowing moisture to escape through the wall.

Frequently Asked Questions

Does cavity wall insulation always cause damp?

No, insulation that is correctly installed performs as intended. Problems arise when moisture enters the masonry and can bridge from the wall into the insulation. Damp is usually the result of this water bridging, not the insulation alone.

Can cavity wall insulation lead to my home losing heat?

The primary function of cavity wall insulation is to improve the energy efficiency and heat retention of a property, however as we have discussed, moisture counteracts this heat retention.

Any moisture that is allowed to saturate insulation will cause it to create a ‘thermal bridge’, allowing heat to pass through the insulation and out of the external wall.

For insulation to do its job, it must be kept dry as the highly porous insulation will uptake large amounts of water if given the chance.

What are the signs of damp?

Penetrating damp occurs when rainwater soaks into the external walls. Signs linked to wet cavity wall insulation include:

- Visible moisture marks on the external wall of a property

- Salt efflorescence that takes the form of a white, powdery substance that is caused by water ingress

- Damage to exterior walls, including cracked bricks & crumbling mortar

- Water marks on interior walls that could cause paint or wallpaper to peel

- Green growth such as lichens, mildew and algae on exterior walls

- A musty, damp smell

The most important thing to do if you think your property is suffering from penetrating damp is to identify whether the moisture is attacking the external wall. Cracked bricks or render, spalling bricks and generally poor condition of the masonry will indicate that wind-driven rain is being absorbed into the wall.

If you have more questions, we are here to help with our in-house team of experts. You can chat to them by emailing [email protected].

Ready to start? Take our handy quiz to get personalised recommendations and find the right products for your project in a few clicks.

This article was written by the Emperor Technical Team, a group of experts with an average of over 25 years experience in the building industry. They work daily with homeowners, tradespeople and specification professionals to deliver practical, expert guidance that promotes long-term results, supports wall health and helps create homes that are prepared for the future.