Waterproofing Render – Expert Guide To Protecting Render

Like any exterior wall, ensuring render is ready for the Great British weather is crucial for keeping it looking attractive and for ensuring your home is dry.

Here at Emperor Paint, homeowners often ask us whether render is waterproof and what they can do to stop water damaging their home.

In this guide we cover:

- Whether render is waterproof

- Why waterproofing matters

- What products provide waterproof protection

Is Render Waterproof?

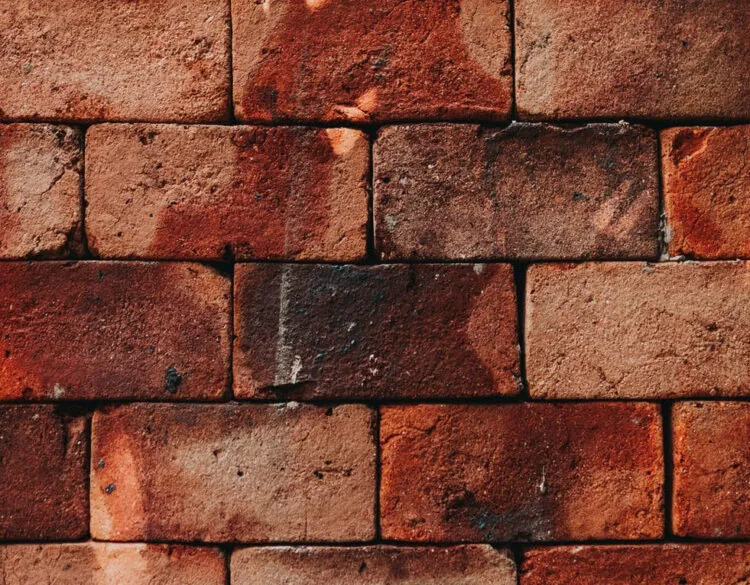

Many homeowners assume building materials like render, brick and other masonry surfaces are waterproof.

The truth is they are all porous, meaning that they absorb water. The more porous a surface, the more water it can hold and the faster damage develops.

When people talk about ‘waterproof render’ they usually mean render that stops rain penetration.

Technically speaking, waterproof means a surface that is completely impermeable to water. That level of protection isn’t good for exterior walls, because it would block water vapour from escaping from inside the building.

The goal for exterior walls is to reduce the amount of water entering while maintaining as much breathability as possible.

How well a render does this often depends on its composition. Renders come in a range of forms, with the weather resistance of the render varying depending on its formulation.

Some of the most common forms of render include:

1. SAND AND CEMENT RENDER

Sand and cement render is the most common form of render that you will find in the UK.

Made from a mix of sand, cement and water, with lime sometimes added, it offers a basic layer of protection but generally absorbs moisture easily.

Its low flexibility means cracks can often appear, while low breathability can also trap moisture that is absorbed by the render.

Because of this, sand and cement render needs extra protection to help it resist rainwater and reduce the risk of damp, cracking and surface damage.

2. ACRYLIC RENDER

Acrylic render has an acrylic resin added to the mix that provides it with more water-resistance and flexibility than a standard render.

It’s available as standard or pre-coloured, removing the need to paint once applied.

While it performs better against rain, it generally has low breathability and can trap moisture, particularly on older walls.

This means acrylic render still benefits from added protection to help it reduce water absorption, ideally without further compromising breathability.

3. SILICONE RENDER

Silicone render is often considered the most modern, top performing option when it comes to render.

The silicone content makes the surface water repellent while maintaining higher breathability than other forms of render. This combination allows it to perform longer than traditional renders, as moisture is often the driver of damage to the render.

Like acrylic render, it’s often supplied as a pre-coloured, ready-to-use system, so doesn’t require painting to create an attractive finish.

Silicone render does come at a higher cost, and some can be susceptible to discolouration if not cleaned periodically.

The water repellent properties of silicone render make it the most effective render at reducing water absorption, though it will uptake some moisture over time. Importantly, the high breathability of silicone render means any coating applied to it should not compromise its breathability.

4. LIME RENDER

Lime render is a more traditional form of render that is made from lime and sand that forms a flexible, breathable mortar.

Thanks to its breathability, lime render allows moisture to pass through and evaporate naturally, helping keep walls dry. However, this also means it absorbs rainwater, relying on its ability to release the moisture rather than prevent it entering in the first place.

Used mostly on traditional buildings, it’s an eco-friendly option that moves with the structure to help prevent cracking.

To maintain its performance, any coating applied must also be highly breathable.

5. PEBBLEDASH

A popular form of render in the 1970’s, pebbledash is a form of render that has stones and rocks added to the composition of the render to provide a hard, textured finish.

Over time, the stones can loosen or fall out, leaving the base layer exposed. This subsequently means the render is left with little resistance to water absorption, leading to issues relating to penetrating damp, that require other measures to be taken in order to keep the fabric of the building dry.

Although often seen as dated, painting pebbledash is a popular way to refresh its appearance and give a cleaner, more modern look while adding extra weather protection.

Why Should Render Be Waterproof?

Ensuring render is able to resist water absorption is crucial if you want to mitigate the problems that are caused by moisture.

Moisture is the single biggest cause of building material deterioration, especially in the UK where our homes are exposed to large amounts of rain almost all year round.

While render provides a protective layer, it can still absorb water from rainfall. Over time, that moisture can lead to several problems for your home.

1. Structural Damage

When water enters the wall, it can undergo a freeze-thaw cycle and freeze in colder months.

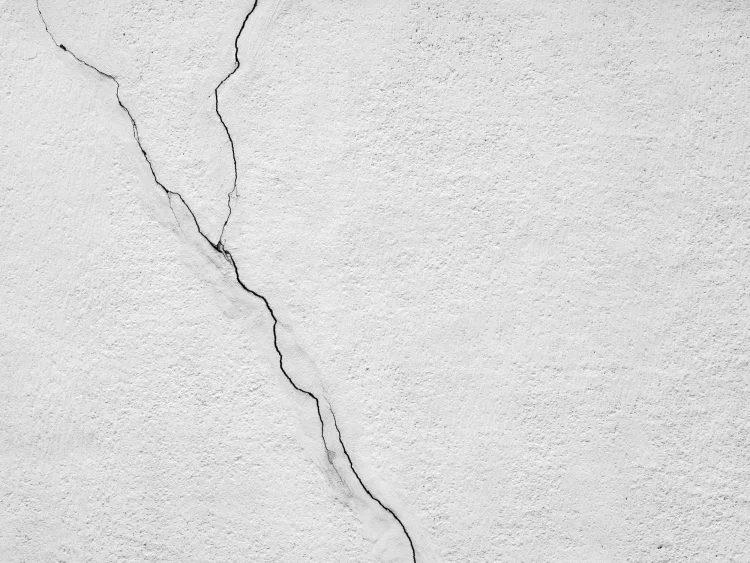

When water freezes it expands, causing movement within the render, which in turn can cause cracks to open.

These cracks allow even more water to enter the render, which causes larger cracks and creates a continuous cycle of damage.

This problem is made worse with renders that have low breathability, as they help to trap this moisture within the wall.

2. Penetrating Damp

Penetrating damp is the process of rain soaking from the outside wall to the inside wall.

Solid wall homes are especially vulnerable because there’s no cavity to stop the moisture.

Once moisture reaches the interior wall, it can lead to damp patches, mould and damage to paint and wallpaper.

While particularly a problem for solid walls, properties with a cavity wall are not immune to the problem when insulation is poorly fitted or there is debris within the cavity. This means that a bridge can be formed between external and internal wall, allowing moisture to travel through into the interior of the property.

The only way to prevent penetrating damp is to stop moisture entering the external wall in the first place.

3. Heat Loss

Something many homeowners are not aware of is that moisture is a key driver of heat loss.

Wet walls transfer heat quicker than dry ones. Studies have found the damp content of just 5% can lower the insulating properties of a material by 50%. With 35% of a house’s heat being lost from the walls alone, by having exterior walls that are saturated with moisture, you are at risk of losing significant amounts of heat from your home.

This heat loss will result in your home having lower energy efficiency and make it more difficult to heat your home.

Learn more: How wet walls lose heat

4. Appearance

Water absorption on exterior walls does not just have an impact on the performance of the wall.

Consistent exposure to high-moisture levels will have a significant impact on the appearance of the render.

Damp patches, discolouration and the growth of lichens can all lead to rendered walls looking dirty, especially with lighter colours.

The Signs Of Water Penetration

There are a number of things that you can look out for in order to establish whether your render is suffering from water penetrating into the substrate.

These include:

- Darkened patches on the render

- Damp and crumbling interior walls

- Cold, hard to heat rooms

- Signs of black mould

- Hairline cracks on the render that increase over time

Any of these signs can indicate that moisture is finding its way into the render, either through a defect like a crack or simply by soaking into the pores of the render.

If the source of the moisture is not resolved, the problems will only worsen over time. That’s why it’s crucial to prevent water ingress as soon as possible.

What Is The Best Way To Waterproof Render?

As we have already mentioned, advanced silicone renders already have waterproof protection. This is an isolated case however, with most forms of render generally having poor resistance to weathering.

There are three main types of products that are designed to reduce the water absorption of render:

1. Sealer

Sealers are clear coatings that are designed to stop rain from absorbing into walls by creating a waterproof film on the surface.

While they block water initially, this film also traps any moisture inside the render. Over time, the trapped moisture leads to damp problems, damage to the render and eventually causes the sealer to fail after a matter of years.

This cycle often leaves render in worse condition than before the sealer was applied.

2. Masonry Cream

Masonry cream is a modern alternative to traditional sealers, offering invisible protection to exterior masonry and render.

Instead of forming a film on the surface, they absorb into the render and line the pores of the material.

Once absorbed, they chemically bond to create a water repellent surface that still allows water vapour to escape.

As they offer an invisible finish, they maintain the natural look of render without altering the appearance in any way.

Like anything, not all masonry creams perform the same. The level of water repellency, durability and breathability can depend on the formulation.

3. Masonry Paint

Masonry paint is the most common way to protect render from the elements.

There are several types available, including acrylic, pliolite, limewash and silicone.

Most standard masonry paints in the UK are acrylic-based. While often referred to as ‘weatherproof’ or ‘weather resistant’, acrylic masonry paint can absorb moisture. This coupled with limited breathability mean they do not effectively manage moisture levels.

This is why most masonry paints come with a lifespan of anywhere from 1-10 years, as over a period of time moisture causes the paint to fail.

NANO-TECHNOLOGY

While there are several ways to protect render, performance varies from product to product. The key to long-term performance is reducing water absorption without compromising breathability, which standard masonry paint and sealers struggle to do.

This is where nano-technology comes in, which is the latest advancement in exterior paint science.

It works on a microscopic level where once applied, it bonds to the wall rather than forming a solid coating over the top of it.

This allows it to change how the surface reacts to water, creating a surface that water cannot attach to. Instead of soaking in, rain is repelled.

By lining the pores rather than sealing them, air and water vapour can still pass through naturally.

This means that render is able to repel rainwater, while maintaining natural breathability.

This nano-technology is what allowed us to create Emperor Masonry Paint and Emperor Masonry Creme. Both use it to create a super hydrophobic surface that keeps render dry without compromising breathability.

To show how they can help protect render from the elements, a UKAS accredited testing laboratory carried out a series of tests.

The tests found:

- There were no signs of deterioration after 25 years of weathering

- Water absorption was reduced by up to 96%

- Breathability was not compromised, with SD values of 0.03 and 0.01 respectively.

- Walls were kept up to 6°C warmer than untreated walls

Learn more: How Emperor Paint products were tested

Frequently Asked Questions

Does the paint have to be compatible with the render?

Absolutely, this is a crucial part of painting render that you must consider.

If a paint is not compatible with a render, it will simply fail after a matter of months.

For example, silicone render must be coated with a silicone-based paint like Emperor Masonry Paint. This doesn’t apply to acrylic render, which can be painted with an acrylic-based or silicone-based paint.

In the case of lime render, this must be painted with a highly breathable paint due to the porosity of lime.

Does render have to be dry to paint?

Yes, you must ensure render is completely dry before painting.

This is the case whether it is new render, or old render that has been exposed to rainfall recently. Generally, you must wait at least 2-4 weeks once new render is applied to be able to paint it.

If you have more questions, we are here to help with our in-house team of experts. You can chat to them by emailing [email protected].

Ready to get started? Take our handy quiz to get personalised recommendations and find the right products for your project in a few clicks.

This article was written by the Emperor Technical Team, a group of experts with an average of over 25 years experience in the building industry. They work daily with homeowners, tradespeople and specification professionals to deliver practical, expert guidance that promotes long-term results, supports wall health and helps create homes that are prepared for the future.